Matrix

IntelliZone® Proximity Detection System

For Underground Mobile Equipment in Coal or Metal/Non-Metal Mining Operations

Low-visibility or obscured line-of-sight locations

Shaped Dynamic Zones

Worker Tags Required

IntelliZone® Features

IntelliZone enhances miner safety without degrading productivity levels.

Shaped, dynamic zones for precise worker location

Workers wear a personal device

Lowest cost of ownership

For all section mobile equipment and light-duty vehicles including continuous miners, shuttle cars and LHDs

Proven in Australian, U.S. and South African mines

Robust and compact locators

IECEx approved

Minimal and easy maintenance and component replacement

System Overview

1

Locator

2

Driver

3

Machine-Mounted Locator (MML)

4

Controller

5

Power Supply

6

Splitter

7

Dome Antenna

8

Half-Wave Antenna

9

Enhanced Status Screen

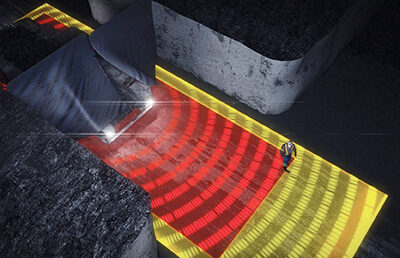

SharpZone™ Technology for Precise Programmable Awareness Zones

Matrix’s leading-edge SharpZone technology creates equipment-specific straight line and angled safety areas for the most effective Caution and Shutdown zones. These zones help protect miners from mobile equipment injuries and minimize nuisance warningsor shutdown. For example:- Mobile haulage awareness zones vary based on speed and direction of travel. Higher speed means longer forward zones to allow for higher stoppage time. Mobile haulage awareness zones can “see” through curtains to help avoid worker collisions.

- Zones around CM tail automatically shrink in cutting mode and expand while tramming.

- Customized “green” zones can be generated within the awareness zones to allow operators to stand, kneel or, if appropriate, ride in safe locations without setting off a zone alert.

Forward Zones Extend as Speed Increases

As shuttle car or loader speed increases, the forward zones increase in length to accommodate the longer required stopping time.

The zones can “see” through barrier curtains which helps protect workers.